October 18, 2023

October 18, 2023

The difference between multi-layer shuttle racks and four-item shuttle racks

October 18, 2023

October 18, 2023

Return

Return

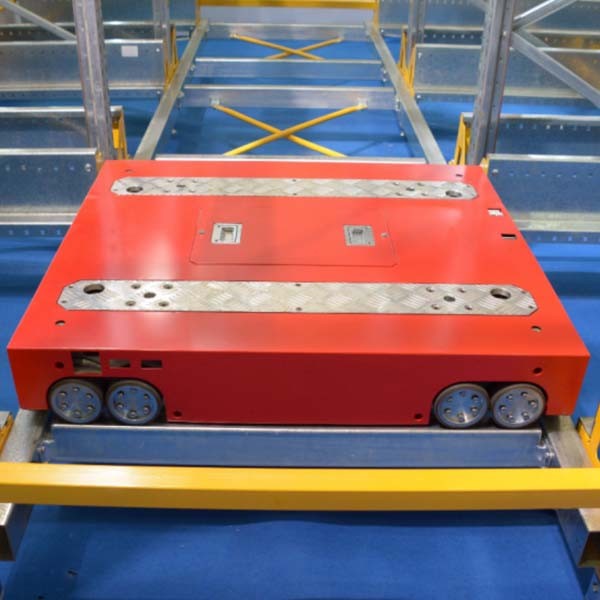

The four-way shuttle racking system consists of a four-way shuttle, a hoist, a conveyor system, a racking system, and a WMS/WCS control system. It has the characteristics of high storage density, stable system operation, and high safety redundancy. The four-way shuttle can automatically switch between the longitudinal storage lane and the horizontal transfer channel. In addition to having the characteristics of a general shuttle, it is more suitable for warehouses in complex environments. With the support of the wireless network, each unit is connected to each other, and under the dispatch of the WMS WCS upper-level management and control system, they respond to each other and complete the inbound and outbound operations of goods. Four-way shuttle rack systems are widely used in food, beverage, dairy, pharmaceutical and other industries.

The multi-layer shuttle racking system consists of multiple groups of shuttles (running on shelves on different levels), fast elevators, box conveyor lines, sorting lines and WMS/WCS. It is an alternative, more advanced and efficient, Automatic storage mode suitable for container logistics. Multi-layer shuttle rack systems are available in single- and double-depth designs, as well as two-way and four-way designs. The system is widely used in the logistics model of light parts and boxes such as auto parts, electronics, and biopharmaceuticals.

What is the difference between a four-way shuttle racking system and a multi-layer shuttle racking system?

1. Structural aspects

The four-way shuttle can run in four directions: "front, back, left, and right" and has two sets of wheel trains, respectively responsible for movement in the X and Y directions, while the multi-layer shuttle has only one wheel train. The four-way shuttle solves the problem that multi-layer shuttles cannot move horizontally, which is also the unique feature of the four-way shuttle.

2.Technical aspects

The problems faced by multi-layer shuttle vehicles are mainly positioning, power supply and communication problems in the tunnel. The early multi-layer shuttles basically used sliding wires for power supply, which is a more traditional power supply method and the design is relatively simple, while the four-way shuttle uses built-in battery power supply. In addition, the four-way shuttle must also solve problems such as lane changing, vehicle avoidance, vehicle dispatching, and layer changes, so technically the four-way shuttle is slightly better.

3.Application

Four-way shuttle racking systems are mainly used in food, medicine, tobacco, cold storage and other industries, while multi-layer shuttle racking systems are used in light parts industries such as auto parts, electronics, biopharmaceuticals and so on.

Generally speaking, the price of four-way shuttles is higher than that of multi-layer shuttles, but the utilization rate of four-way shuttles is high, the actual number required is small, and the number of supporting hoists is also much smaller, so the two

The selection of the candidate should be determined based on the specific project.