May 30, 2024

May 30, 2024

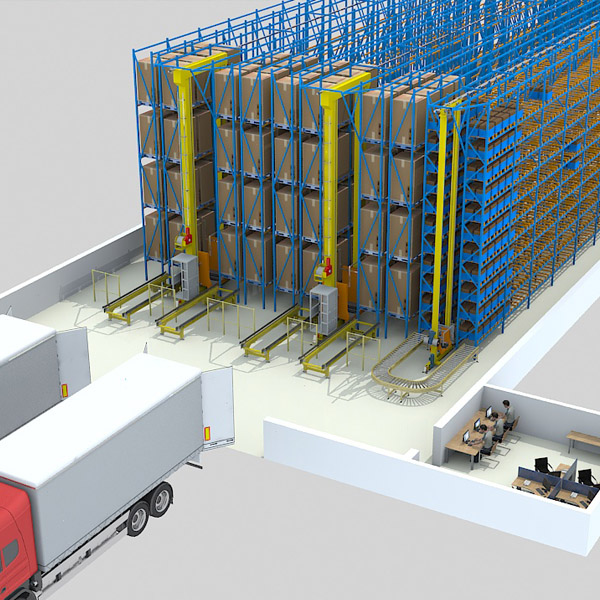

Automated warehousing logistics rack, an important development direction of modern warehousing

May 30, 2024

May 30, 2024

Return

Return

Automated three-dimensional storage rack is an efficient storage solution for modern storage needs, which can realize fully automated operations and is a sweet cake for cost reduction and efficiency increase. Through the application of automation technology, the rack can optimize the use of space, reduce the footprint, and improve the storage density of the warehouse.

Automated warehousing logistics rack can often be designed higher to make full use of vertical space and improve storage efficiency. The ability to automate storage, sorting, replenishment and sales significantly reduces the need for manual intervention. It can automatically identify different brands, types, sizes and quantities of goods, and carry out accurate statistics and distribution. Automatic identification of inventory time, qualified products, unqualified products and returns and other information, to achieve first-in-first-out, to ensure the freshness and accuracy of inventory goods.

Single-layer bearing capacity up to more than 3000kg, the height can be designed to more than 30 meters. It can be seen that automated three-dimensional storage rack with its high degree of automation, space saving, safety, reliability and intelligent management characteristics, has become an important development direction of the modern storage industry. Today is the era of intelligence, cost reduction and efficiency is the key to double benefits, warehousing to achieve intelligent transformation and upgrading, is the trend of The Times.

RECOMMEND INFORMATION

-

Are shuttle racks accurately positioned goods?February 13, 2025

-

Shuttle rack where good?January 15, 2025

-

Cold storage intelligent rack, space utilization artifactAugust 16, 2024

-

Lift warehouse racks, efficiency is fullJuly 11, 2024

-

What kind of semi-intelligent warehouse rack isJuly 09, 2024

-

Shuttle rack priceJuly 08, 2024

-

How much is the shuttle rackJuly 04, 2024

-

Shuttle rack wholesale priceJuly 02, 2024