May 12, 2022

May 12, 2022

A Close Look at Eyda Drive In Racking Rail

May 12, 2022

May 12, 2022

Return

Return

Part 1

At the beginning of the rail, we make 3 small pieces of steel welded together and have a downward angle. Why do we make a design like that?

When the forklift enters the rail if it is in a lower position than the rail. It can smoothly slide into the rail, it won’t be a barrier when it moves on the rail.

Although this design makes the processing cost a little bit higher, it can avoid damage to the forklift and the rack.

Part 2

You can see the at the rail of left, it is not a right-angle design. It is an inclining design. This design will make the palletized cargo can land on the rail in a sliding way when the position is not placed well. Then It can avoid any falling of the cargo from the pallet.

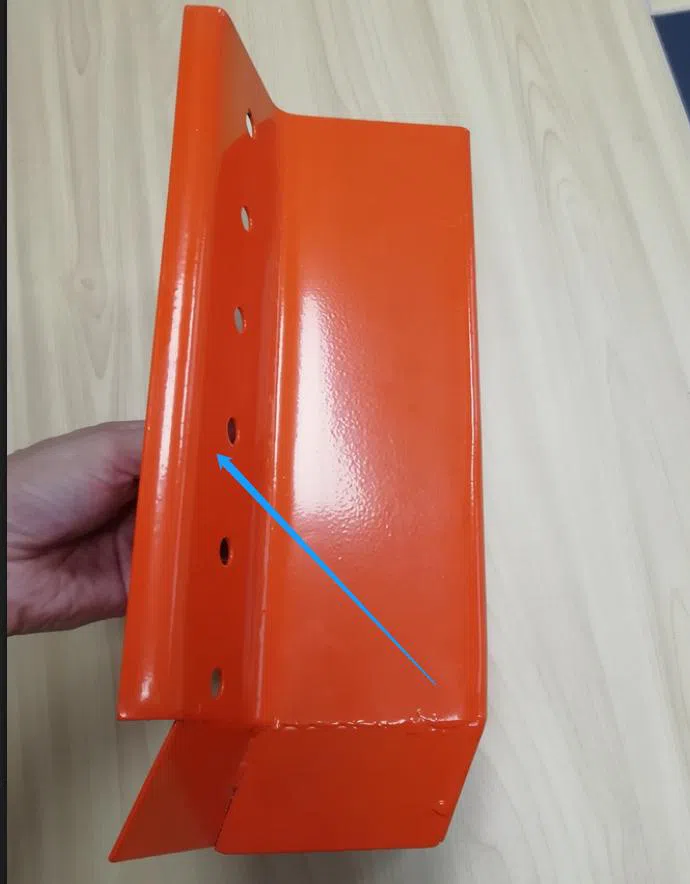

Part 3

You can see the bending of the rail, we have 4 places. This design will make the power of the support stronger. Although the cost of the material and the processing is more.

RECOMMEND INFORMATION

-

A Close Look at Eyda Drive In Racking RailMay 12, 2022