July 07, 2022

July 07, 2022

What are the advantages and disadvantages of warehouse gravity roller racks for storing goods

July 07, 2022

July 07, 2022

Return

Return

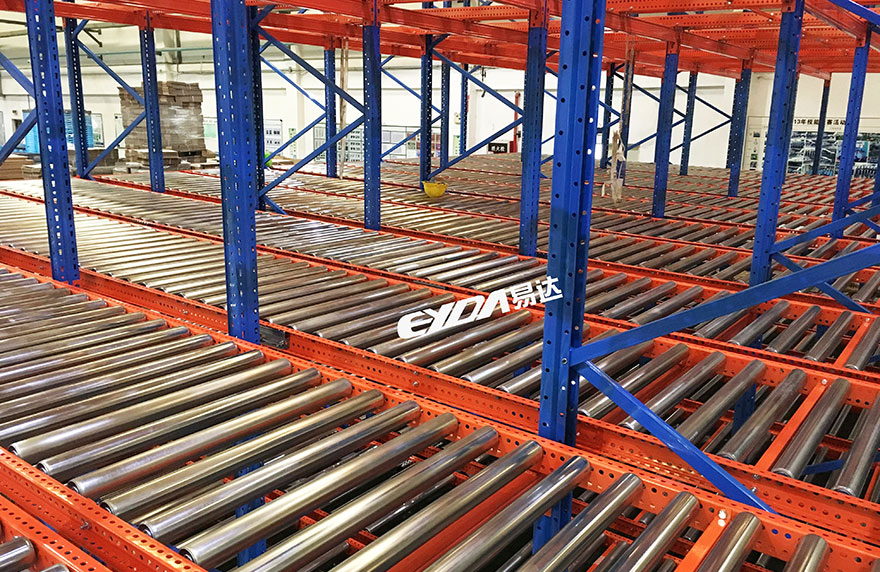

Customers who are not familiar with storage shelves may not know the principles and advantages of gravity roller racks. Eyda storage shelf manufacturer introduce to you.

1. What is a warehouse gravity roller rack?

Gravity racks are also called roller racks, which are composed of uprights, beams, roller systems and separation systems. They are storage racks that need to be customized. The warehouse gravity rack can ensure the principle of first-in, first-out, and the pallet with goods will slide down quickly along the drum under the action of gravity, and then separate at the end, which is very conducive to pick goods. This is why more and more companies choose gravity roller racks.

Gravity shelves are similar to general shelves from the front, but the depth of gravity shelves is much deeper than general shelves. It can store goods intensively on a large scale, thereby reducing the number of aisles and effectively saving the area of the warehouse.

At the same time, the depth and number of layers of the shelves can be determined according to the needs. After changing from ordinary shelves to gravity racks, 50% of the warehouse area can be saved.

Because the drum is an inclined structure, the height of the gravity roller rack is generally not designed to be too high, generally below 7 meters. The load-bearing capacity of a single floor can reach more than 2 tons.

2. the main application areas of gravity racks:

A. Large-scale gravity racks have a large storage capacity and can be stored in large quantities. They are mainly storage shelves;

B. It is suitable for the storage of goods with fast turnover and first-in-first-out requirements, such as applications in breweries, food factories and various production lines.

3. the advantages of gravity roller racks:

A. It can guarantee the first-in first-out of the goods.

B. It is a high-intensity shelf storage system with extremely high space utilization rate, which is more space-saving than ordinary pallet shelves.

C. When loading and unloading, the forklift or roadway stacker has the shortest stroke.

D. It can prevent the theft to the greatest extent. With this form of shelf, outsiders can only access the first pallet of goods at the top of the chute, so the theft rate of goods is greatly reduced.

E. Gravity racks are suitable for zero-in or whole-in and out, especially for large-scale in-out and storage. If the incoming and outgoing system is connected to the automatic conveyor belt, the throughput capacity can reach 280 boards/hour.

4. the disadvantages of gravity roller racks:

A. The investment cost is relatively high. The cost of general gravity racks is about 5 times that of ordinary shelves, but compared with automated storage systems, it is relatively low.

B. Gravity racks have high requirements on the manufacturing and processing of pallets and shelves, otherwise it is easy to cause chute blockage, and at the same time, the daily maintenance requirements are also high.

RECOMMEND INFORMATION

-

What role can the double-deck roller rack play in the workshop?August 01, 2025

-

Is the roller rack a mobile operation system?July 24, 2025

-

What is the storage capacity of the roller rack?July 15, 2025

-

Gravity storage rack, intensive storageSeptember 12, 2024

-

Does the roller rack belong to the heavy rackJuly 08, 2024