June 13, 2022

June 13, 2022

Aipak Guangdong Automated Storage Asrs Systems

June 13, 2022

June 13, 2022

Return

Return

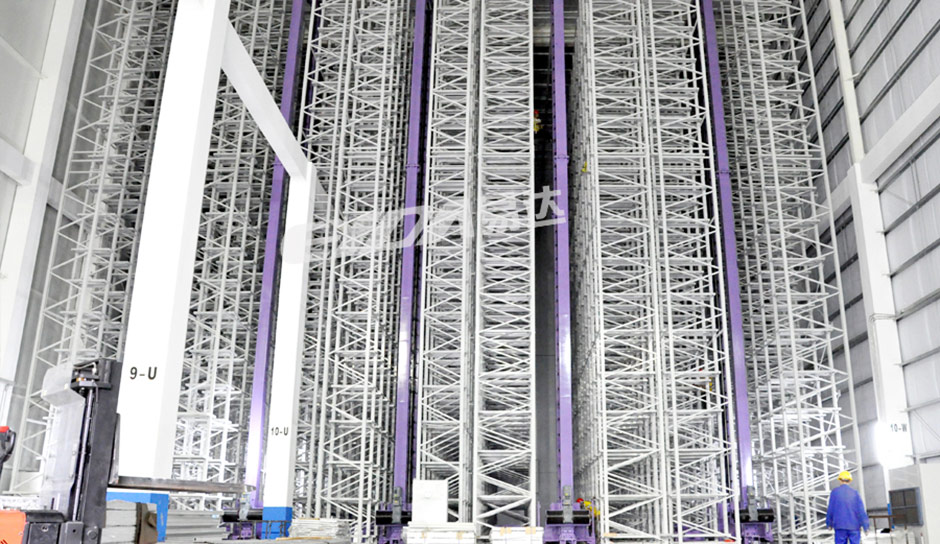

Summary: EYDA Storage Equipment Co., Ltd. designed automated storage system warehouse for it. Automated storage can maximize their warehouse & reduce labor costs.

Customer Name: Guangzhou Aipak Auto Parts Co., Ltd.

Project Industry: Auto Parts Industry

Shelf Area: 1000 square meters

Project Location: Guangzhou China

Customer introduction:

Aipak company produces auto body frames and other parts, produces and processes key auto parts (including instrument cluster), fine punching dies, precision cavity molds, mold standard parts, mold fixtures, and thick precision parts.

It is one of the major suppliers of Japanese auto parts in Guangdong area. Main customers include Guangzhou Honda, China Honda, Dongfeng Nissan.

Project follow up:

Aipak company mainly produces and processes auto parts products. Its requirements are large storage capacity of goods and high storage and retrieval efficiency.

Therefore, EYDA Storage Equipment Co., Ltd. designed automated storage system warehouse for it. Automated storage can maximize their warehouse & reduce labor costs.

Real scene effect:

RECOMMEND INFORMATION

- Belle International Rack Supported Mezzanine

- Japan E-DICS INC company shelf storage rack

- Sumitomo Chemical Heavy-duty Pallet Racking

- Chenzhou Grain and Oil Machinery Warehouse Suspended Beam-Type Shelving

- Customized attic cantilever shelves by China Aviation Fast Company

- Changlong Flavor and Fragrance Company's custom-made roller rack

- Anchen Protein Biobubble Double Deep Warehouse Rack

- New One Chemical Coatings High Position Pallet Rack

- Ouou Medical Loft Mezzanine Shelving

- Wenzhou Bookstore Heavy-duty Laminate Rack

- Zhongxin Da Technology CTU Material Box Shelving

- Southern Logistics Group Heavy-duty Double-deep Rack System